Activity-Based Costing

ABC classification is based on the Pareto principle, which maintains that 80% of a system’s outcomes are determined by 20% of its inputs. The Pareto principle, often called the 80/20 rule, is more simply expressed as the idea that a minority of inputs results in the majority of outputs. While the core principles remain the same, its application can be fine-tuned to cater to the unique demands and dynamics of QuickBooks ProAdvisor different industries. Let’s explore how ABC analysis adapts to different sectors, which can help you unlock its full potential in your specific context. Class B or Category B items contribute a respectable 15% of your sales value and make up around 30% of your inventory.

(i) Production overhead costs are high in comparison to the various direct costs;

ABC analysis helps the automotive industry to analyze resource utilization and equipment performance. It also helps automotive manufacturers to get real-time information on raw materials. Inventory managers should use an automated system to retrieve inventory easily, and the system also helps manage lead times and demand planning. As the sales increase, demand for the product also increases, so you need to increase the stock to avoid stock-outs. Keep on analyzing the performance of each class item in the market and recategorize the items based on their cost and performance. So regular counting of class A items gives you a significant marketing impact and increases the sales performance.

Process improvement

With ABC, you can determine the cost of each activity involved in producing a product or service. By doing so, it enables you to ascertain which activities are driving costs and where there is potential for improvement. The ABC model has its roots in the behavioral psychology theories proposed by B.F. Skinner emphasized a systematic examination of behavior as a result of environmental stimuli (antecedents) and their consequences.

Product Mix:

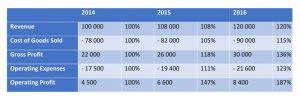

A useful broad perspective on this is – activities consume resources (and might be called ‘cost objects’ by your accountant); products, customers and manufacturing channels consume activities. In conclusion, cost calculation in ABC is vital for achieving a more accurate representation of overhead costs related to producing or providing specific products or services. By identifying necessary expenditures, grouping them into appropriate cost pools, and determining cost driver rates, businesses can make better financial decisions and improve profitability. ABC is more accurate primarily because it assigns overhead costs based on the activities that actually cause them, rather than distributing them evenly across all products or services regardless of use. It takes into account the true consumption of resources for each product, thus providing a more precise picture of product costs and profitability. Traditional costing methods often oversimplify these allocations, leading to less accurate costing information.

- On the contrary, the line is too long if dropping items can increase profits.

- Initially, you’ll want to define the primary activities—these are the essential tasks that directly contribute to the delivery of your product or service.

- The process of replenishment can also be called reordering, which depends on the category of products, as per their own decided controls.

- ABC helps managers to identify and control the cost of unused capacity.

- From the 1990s to the present, the ERP system has supported ABC analysis with other inventory management methods.

Trending Resources

Now, let’s dive into the practical details, equipping you with best practices and strategies to guarantee a successful implementation. So, you’ve implemented ABC analysis in your business, neatly categorizing your inventory into A-list superstars, reliable B-listers, and essential C-players. It’s about unlocking hidden efficiencies, streamlining processes, and ultimately boosting your bottom line. The Pareto Principle suggests that 20% of your products (the A-listers) generate a whopping 80% of your sales value. Conversely, the remaining 80% (B and C-listers) contribute the remaining 20% of your sales.

Someka ABC Analysis Template

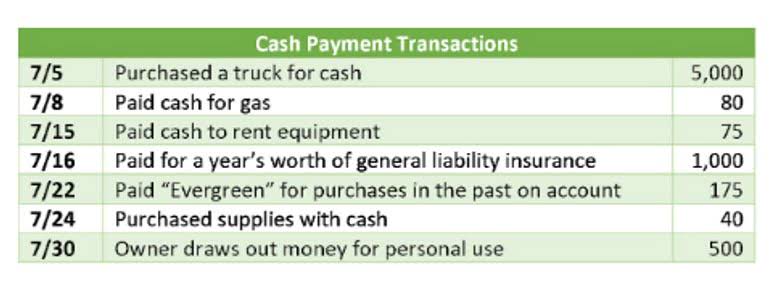

The process involves several stages that lead to a more transparent and accurate understanding of product costs. Imagine a manufacturing company that incurs a significant electricity bill, mainly due to labor hours. In this case, labor hours become the cost drivers, as they directly impact the total electric bill.

Lisa has a business of sweaters, and over time, her business has achieved tremendous success. Lisa, in search for varieties and additions to her sweater inventory, has filled in 180 types of sweaters instead of just 50 types. She now realizes that this business is seasonal, and she has already invested a lot. ABC analysis is derived from the term “The Pareto ledger account Principle” named after an Italian economist Vilfredo Pareto, also called 80/20 rule.

Ten Things that Need to be Said Regarding Project Management

- This may limit the ability of managers to truly understand and identify the best business decisions about product pricing and targeted production levels.

- This detailed costing methodology ensures that your organization can make more informed decisions in cost reduction and revenue optimization.

- My Accounting Course is a world-class educational resource developed by experts to simplify accounting, finance, & investment analysis topics, so students and professionals can learn and propel their careers.

- Applied to inventory, this means that a small percentage of items typically account for the majority of your inventory value.

- You want to involve employees from across your organization in this process, as their insights are invaluable in identifying the true nature and sequence of activities that take place.

Use an SKU’s consumption volume only when conducting ABC analysis for physically organizing your inventory. The ABC principle is a business communication rule that says each message must be Accurate, Brief and Clear. You check facts and grammar, cut extra words, and define ideas with numbers, plain words or pictures. When you use all three steps in any spoken or written message, people understand quickly and trust you. This profile covers a wide range of companies in various sectors, as repetitive processes are common in many industrial and commercial activities. In some cases finding the activity that causes the cost is impractical.

Inventory optimization

- In order to analyse each product line, product- line managers need to know two factors.

- Lily Hulatt is a Digital Content Specialist with over three years of experience in content strategy and curriculum design.

- Activity-based costing can help you to set an accurate budget that breaks down exactly where your money is going and which products are the most profitable.

- For example, apportioning utilities costs to particular activities is an educated guess, not a ‘to the penny’ calculation.

- Starting with ABC requires a comprehensive understanding of your business processes.

You need to abc principle definition consider the best accounting method of costing for your business. Remember, this ABC formula is most commonly used in manufacturing, where individual products are more easily costed. For example, apportioning utilities costs to particular activities is an educated guess, not a ‘to the penny’ calculation. Accurate pricing of goods and services is one of the most difficult things business owners need to tackle. One that’s going to attract customers because it realistically reflects value and isn’t overpriced.

Responses